|

|

Extracting minerals from the earth safely and efficiently is

our core competency. For a mid-tier gold producer, IAMGOLD

is still a young company. We haven't lost that entrepreneurial

edge. We're driven to be great miners – to mine and process

ore as cost efficiently as we can. Towards that end we have

built a culture committed to continuous improvement and

excellence in execution.

Continuous improvement encompasses many elements

designed to improve the way we work. Its benefits are far

reaching, and a strong continuous improvement culture

forces you to regularly challenge the status quo. We use

sophisticated tools to determine optimum strategies for

mining our assets and improving the efficiency of our mining

processes. We are diligent about managing production costs

and implementing cost-control initiatives to increase

profitability. While profitability is a key focus, it must be

balanced with the need to protect our people, our

environment and the communities within which we operate.

We will never compromise our commitment to operating under

the Zero Harm framework. We demand strong, visible safety

leadership from our site management teams and conduct

rigorous training programs and reviews. This is essential to

make the workplace safer and to improve the ability to spot

and solve problems before they result in an incident.

IAMGOLD's first-rate continuous improvement program

fosters an environment where everyone works smarter,

harder and safer. That benefits all stakeholders.

Gordon Stothart

Executive Vice President and Chief Operating Officer

| Tools to Maximize Operating Efficiency |

| Strategic Resource Development Planning (SRDP) enables mine planners to

assess various long-term strategies for mining resources based on limited drill data. It

works by generating a matrix of high-level "what-if" scenarios, with the preferred case

carried through to detailed analysis. By simulating the re-engineering of deposits to map

out the best ways to develop them, we can challenge assumptions and avoid tunnel vision

in our approach. At Rosebel, we applied SRDP to identify the optimal strategy to address

the increasing proportion of hard rock against a backdrop of a steadily increasing

resource. As a result, our long-term plan has been designed to optimize life-of-mine net

present value by investing in increased grinding capacity and incrementally expanding

the overall throughput capacity. This analysis can also help determine the appropriate

course of action when we experience a significant resource expansion or when there is

a significant change in gold prices. |

|

|

|

Value Stream Mapping (VSM) is used to identify opportunities to improve an

operation from start to finish. The objective is to eliminate wasted time, wasted

material and wasted money. VSM works by creating a map of the process and

pinpointing problems with work flow, such as production bottlenecks. Once the

necessary changes are determined, a future map is generated to depict the

improved process. This enables us to lay out the required resources and the

timeline for executing improvements. It also ensures that we focus on improving

the steps in the value chain that will deliver the most meaningful improvement to

the process. The same mapping tool can also be applied at the micro level,

focusing on activities such as drilling and blasting. At Niobec, we used VSM to

match an increase in mill capacity with hoisting capacity. As a result, milling

capacity increased by 24%. |

|

Focusing on Margins

At IAMGOLD we monitor our margins closely. Given the nature of our business, they

are a more important performance metric than stand-alone cash costs. Higher costs

are correlated with higher gold prices. As prices rise, lower grades of ore become more

economical to mine. By mining these previously uneconomical portions of our resource

base we can optimize the ore deposit and extend the life of the mine. Although we

experience an increase in associated costs, we benefit from an increase in cash flow.

By understanding the correlation between gold prices and production costs, while

retaining operational flexibility, we can react accordingly to movements in the price of

gold to expand or protect our margins. |

|

|

| |

|

|

|

Rosebel – A Star Performer with Significant Expansion Potential |

|

| Producing 395,000 ounces of gold in 2010, the Rosebel mine has been a huge sucess. |

| |

|

|

|

| |

|

|

| |

Rosebel – A Star Performer with Significant Expansion Potential |

|

| |

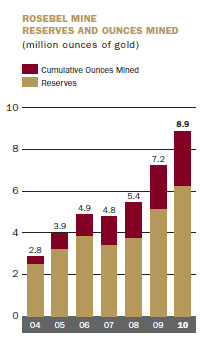

Producing 395,000 ounces of gold in 2010, the Rosebel mine has been a huge success. Since 2004, when the mine commenced operation, 2.7 million ounces of gold have been mined (on a 100% basis) and reserves grew by 3.7 million ounces to 6.2 million ounces as of December 31, 2010. With net reserve growth outpacing cumulative ounces of gold mined by 37%, the potential for continued grow is substantial.

Our focus going forward is on mine optimization. In 2010, we increased the number of leach tanks by 25% to a ccommodate a signifiant increase in throughput, the result of the previous year's mill expansion exceeding design capacity. This year, we are embarking on an aggressive expansion plan that is expected to increase annual production to 400,000 to 450,000 ounces. Spread out over the next seven years, we will invest a further $185 million in this program. With additional grinding capacity and mining equipment, we will be able to maintain mill throughput between 12 and 14 million tonnes per year, offsetting the impact of an ore mix trending towards a higher proportion of hard rock. The expansion will bring gold production forward in time and lower our long-term fixed costs by accelerating the rate of production. |

|

|

| |

|

|

|

Essakane – Ramp Up

to Production with

Expansion Plans |

|

Essakane was the operating

highlight of 2010 |

| |

|

|

|

| |

|

|

| |

Essakane – Ramp Up to Production with Expansion Plans |

|

| |

Essakane was the operating highlight of 2010. In the fourth quarter the mine produced 80,000 ounces of gold. Probable gold reserves at the end of the year were more than 4 million attributable ounces. We estimate that after the first three years of processing soft rock, there will be nine years of hard rock processing. A mine expansion feasibility study is underwayto demonstrate that by doubling hard rock processing capacity to 10.8 million tonnes, we would increase annual gold production from an estimated 315,000 ounces to 450,000 to 470,000 ounces. Pending the favourable outcome of the study, construction is expected to begin as early as the fourth quarter of 2011.

|

|

|

|

| |

|

|